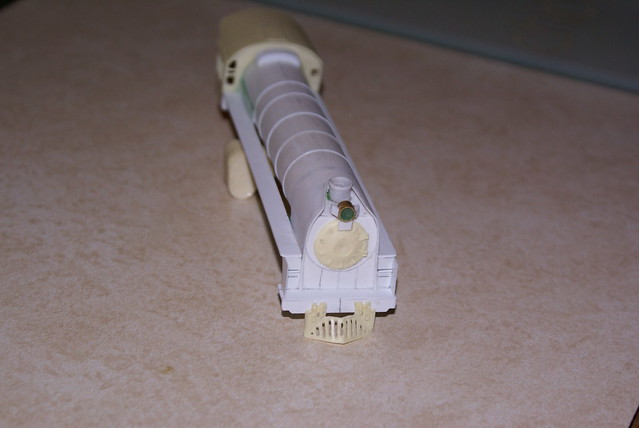

This will be a brief description of the construction of the Strath Hobbies 500 class kit, available through End of the Line Hobbies (Victor Harbor, SA).

To start with, purchased a body-only kit as I already had an old Life Like Proto 2000 SW1 mechanism that was dying for some use, having been stored since 2004. The body only kit retails for $250, while the full kit (with a Hollywood Foundry mech) retails for around the $500 mark.

I was visiting my brother's layout "

Tookayerta" when it was suggested that a 500 class shunter would be an ideal candidate to shunt the industrial sidings on the "to be built" section of his layout. To my suprise, Nick pulled out a A0 sized general arrangement drawing of a said loco, and then comparisons were made between the drawing and photos posted on the Model Etch website of a built Strath Hobbies 500.

I then decided, that there could be a number of alterations made to the kit to make it better represent the prototype.

The problems outlined were easily fixed - these being:

- Roof profile incorrect

- Bogie sideframes too high and too short

- Lack of general pilot detail

- Cab roof issues

- Exhaust stacks incorrectly shaped

So, off the Victor Harbor I went and purchased a kit. On opening the box, you get a number of brass etches for the hood sides, footplate, pilots, steps, end handrails, cab and a pre-formed cab roof. A bag of whitemetal sideframes, air cylinders, horns, air vents, and two types of exhaust stacks. Then there are also polyurethane castings for the fuel tank and hood roof and nose. A seperate envelope is included which protects the decal sheet for the SAR/ANR Red/Yellow livery - if you want the AN version, End of the Line can supply them.

I also purchased extra detail parts in the form of Associated Distributors single armed windscreen wipers (and mirrors) and Model Etch lost wax air hoses.

As seems to be a common problem with the Strath kits, the instructions leave a little to be desired - but there are some relatively decent resolution colour photos of a completed model included, so it makes life a little easier - the photos were kept, while the instructions were discarded.

The footplate folds up quite easily, with the etched pilots then being sweated onto the tabs at each end of the footplate. Then the steps are folded up and soldered together - care needs to be taken here, as the A end steps are slightly longer than the B end steps.

Then the cab was folded into a box and tacked into place with solder - there are some small tabs on the bottom of most parts which fit into slots etched into the footplate - a great idea as it keeps things square (sad I only noticed these after filing a heap of them off!). Once square, I then soldered the cab into place.

Next was the cab roof - this was a two hour job to get sitting square, but with a huge ammount of solder, flux,swearing, patience and burned finger tips (not neccessarily in that order), the roof was fitted and cleaned up using various files, dremel disks and sand paper.

Then it was onto the hood sides - there is a very thin etch with the grilles and various vents - now the kit supplies the air intake vents fitted with later era paper air filters, which if you are modelling a loco from between introduction and the mid 80's you might want to replace the grilles with some fine brass mesh. These needs to be sweated onto the back of the hood etches. Once these are fitted, solder the hood sides to the footplate. Now go and have a beer and relax for a while.

I'll leave it here until the next installment...